CORPORATE & OFFICE PORTFOLIO

WIND RIVER Payments

Madison, WI

Overview

ARCHITECT

Gary Brink & Associates, Inc.

Square Footage

10,500

WIND RIVER PAYMENTS

Financial Headquarters

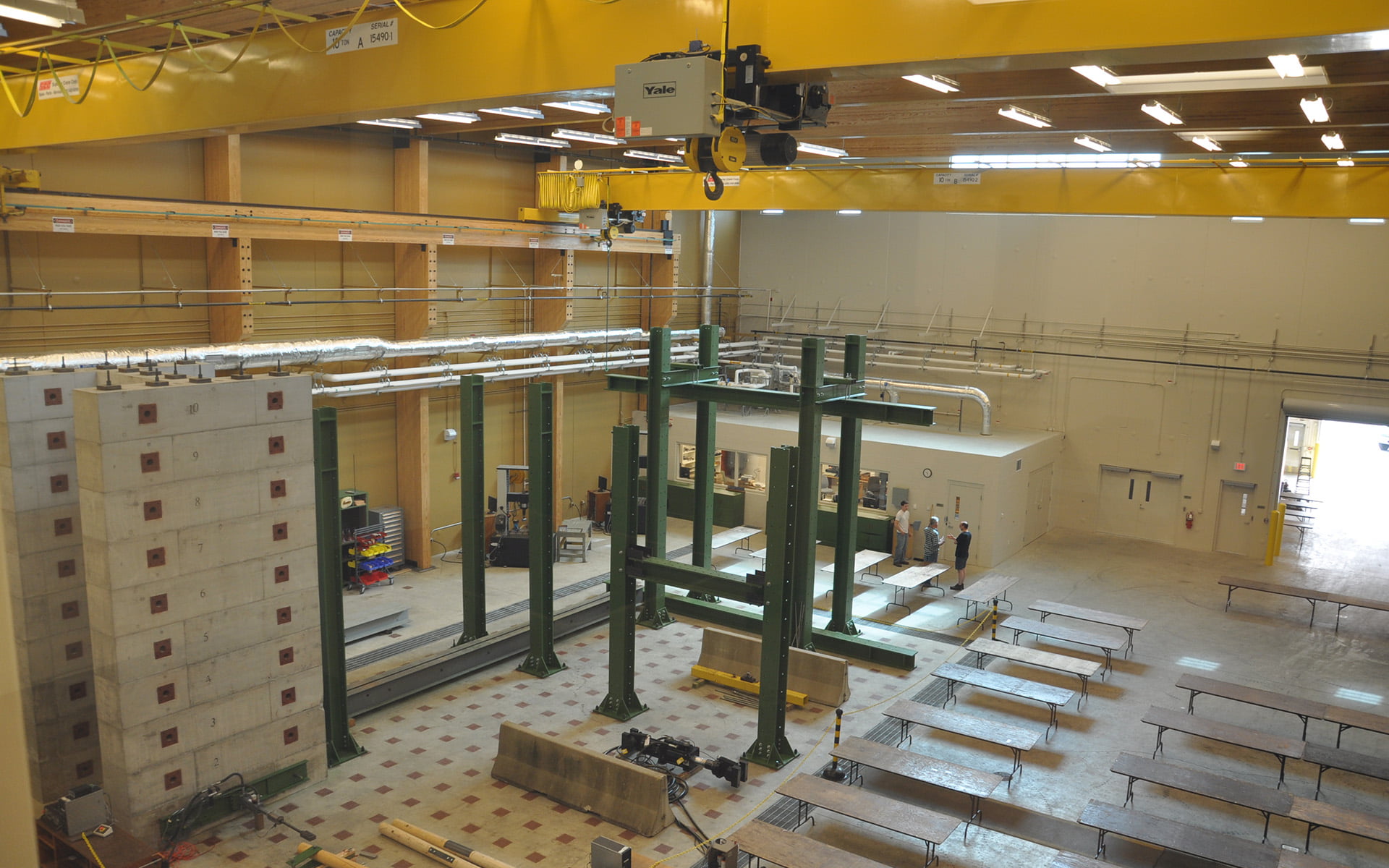

Wind River Payments story exemplars the American dream. Originally renting space from a developer in the American Center, Wind River Payments doubled their square footage, building in that same business park on Madison’s East Side. From the start, this project was a perfect fit; Wind River Payments, a credit card processing firm, is also a family-owned business based on core principles of relationship, trust, and service. Now standing next to giants like American Family Insurance, Alliant Energy, UW-Hospital, and Fairway Independent Mortgage, their dream became a reality. The new 10,500 square foot headquarters is designed to re-create a sense of outdoors and improve employee experiences. The focal point of the building, the glulam timber beams and wood decking, adorn the exterior of the main entrance and are visible as open, vaulted ceilings that are seen from interior working spaces. An open cubical workspace is surrounded by private offices and the employee break room features partition dividers, allowing the room to be utilized as a large conference room or separated into multiple meeting rooms. A wooden trellis framing system overhangs an exterior patio while the site boasts an employee garden, natural prairie grass, and walking trails that tie into the park-wide walking path. Built to house Wind River’s 35 employees, the design allows for expansion of both the building and parking lot to accommodate future growth.

- 2016 ABC Projects of Distinction

RELATED

From the Client

They continue to be fair and perform their work in a timely and professional fashion and have met their schedules on most every occasion. As a company from the dop down, they continue to work hard and strive to provide the best quality and service possible. Their team of administrators, project managers, and superintendents are focused and experienced in every aspect of their projects and are carefully managed to ensure a smooth and positive workflow.

Jeffrey Brenkus

President | Gary Brink & Associates, Inc.